It sounds simple but it is not! Scanning your bow grip is more complicated that, well, simply scanning your bow grip.

When you purchase our Scan ‘n’ Print service, a few things are set in motion.

First of all, you send over your grip. We describe the process here. In general, a tracked service is preferred.

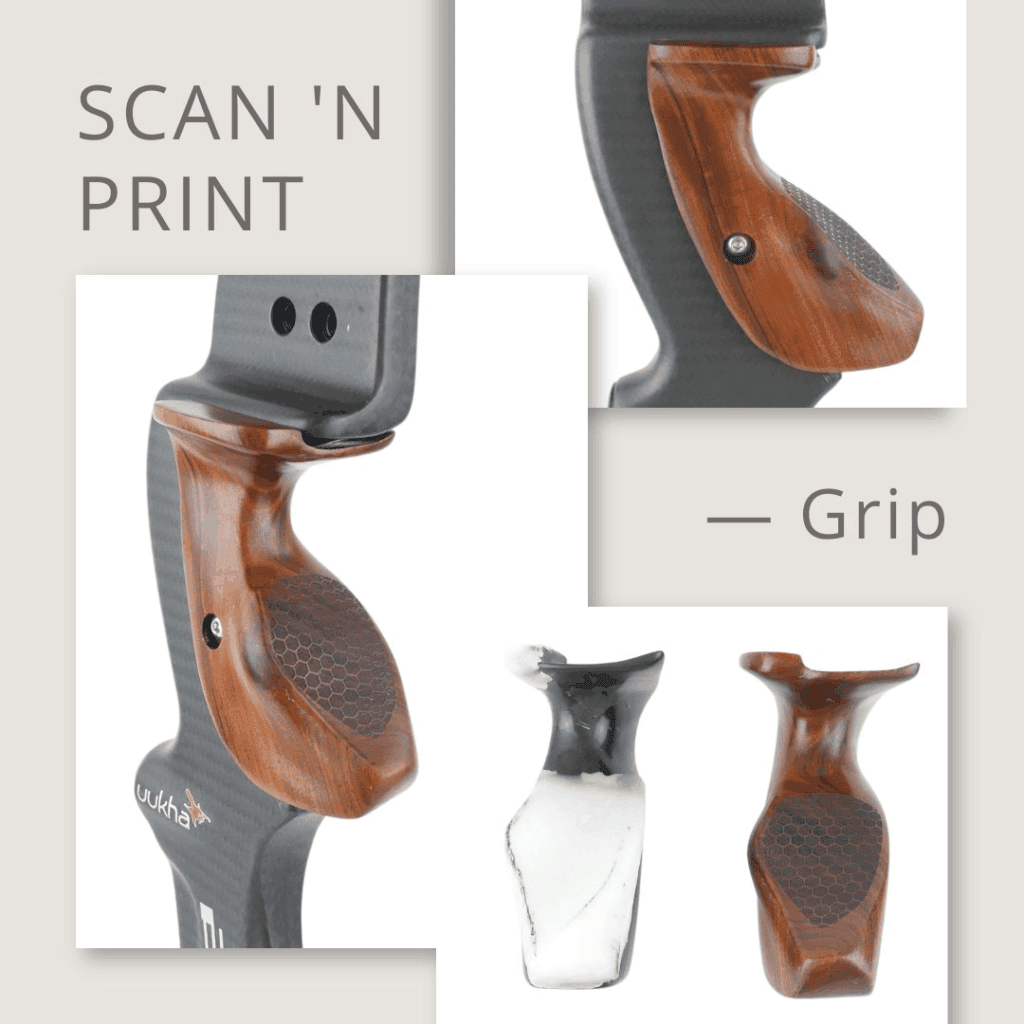

After we receive the grip, we do scan it to a 0.02mm resolution. This results in a huge file. Moreover, due to the geometry of the grip , and especially the concave parts of the fitting, the scan is not immediately useable for printing.

The next step is to clean up the surface and align the scanned grip, in CAD, to the original riser interface it came from. This allows us to verify that everything is in place and the grip is positioned as the owner intended.

Scanning is just the first part of the process. Since the scan is unusable for direct printing, we reconstruct the grip in our CAD software based on the scan. This is a time-consuming process that results in a cad model that is described by its features rather than its geometry. The reproduction is accurate to the tenth of a millimeter but provides the additional capability to fit the grip in any riser supported and to introduce changes requested by the customer either at the point of the reconstruction or in any time in the future.

Since this process is quite time consuming as there is no completely automated way to do it, it reflects the symbolic extra fee for the scanning service.

Then, as soon as the reconstruction phase is completed, the grip geometry is saved under the customer’s internal files and it is available for any future reference. The parametric form in which it is saved allows us to change everything about the grip such as the height angle, palm slant, thumb positioner, width, throat form, palm features and anything you can change on a grip!

All the reconstructed grips are backed up daily, securely and privately. The original STL files are no longer used as they have served their noble purpose to describe your grips to our CAD

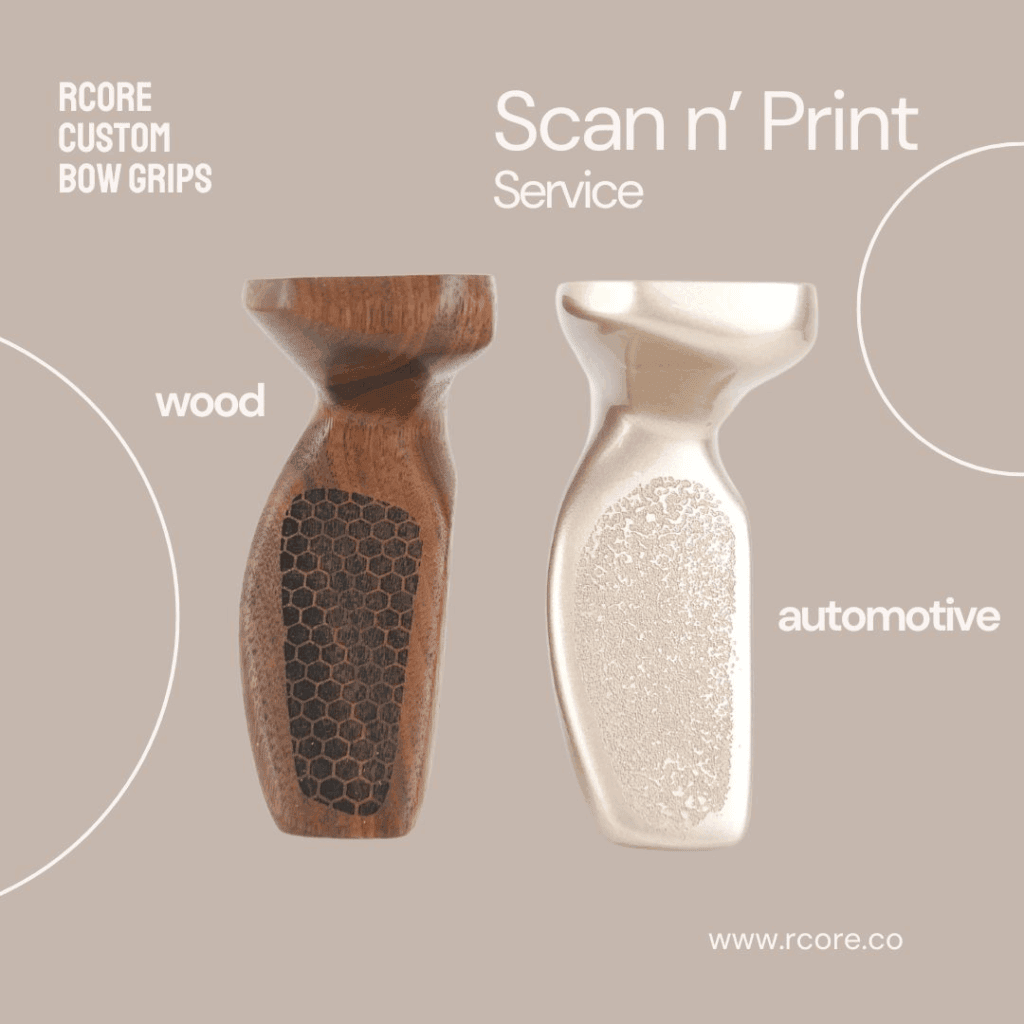

As soon as this reconstruction process is complete, you can have your original grip design in any combination of material/color/feature set you may please. From a simple 3D printed grip to the shiny transparency of the glass-like material, the colorful automotive series and the all time classic, single block, CNC’d wood, your design will be there, no matter what riser you have now, and in the future.

Our scan’n’print service is a unique proposition for your current and future needs

Starting August 29th, the U.S. government may apply import tariffs on certain lower-valued packages shipped to the United States. These tariffs, duties, or taxes are determined and imposed by U.S. customs authorities and are not included in the purchase price or shipping cost.

Please note that any such fees will be the responsibility of the customer upon delivery. We recommend reviewing your local customs regulations for more information.

Thank you for your attention to this matter